Stop the Drift

PESTICIDE DRIFT REDUCTION PRACTICES

Low levels of pesticides continue to be detected in the Clackamas River and its tributaries. This is due to the uses of these chemicals in the urban, right of ways, and agricultural areas. Pesticide drift is one of the contributing factors to these detections. Pesticide drift is the movement of pesticide dust or droplets through the air to any site other than the area intended to be treated. Learn how you can better manage pesticide drift while improving your bottom line and reducing pesticides in our streams and rivers.

These activities will provide benefits to your bottom line and reduce the potential for airborne chemical drift. It is a win-win-win situation for you, wildlife, and the 300,000+ people who get their drinking water from the Clackamas River.

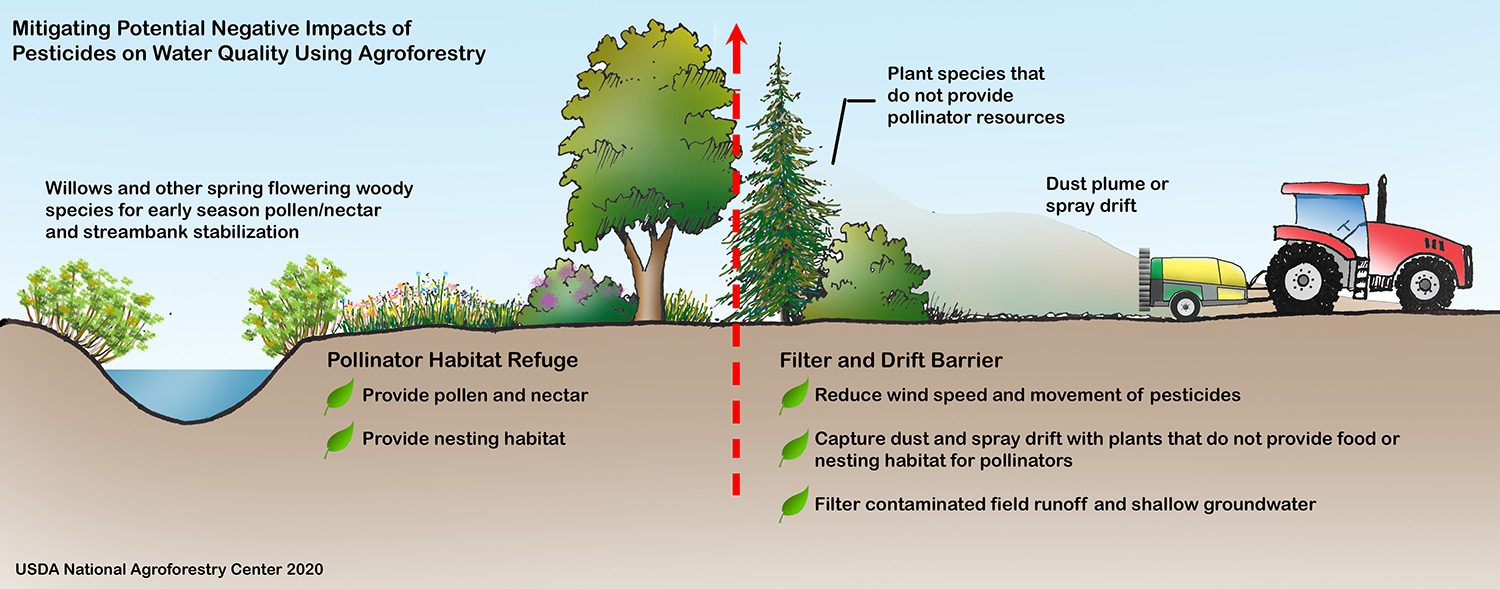

HEDGEROWS

llustration by: Gary Bentrup, USDA National Agroforestry Center

In addition to acting as low maintenance fencing once established, hedgerows can also be designed to filter pesticide drift. Attaining the correct porosity for proper filtration is key to a successful installation.

WINDSOCKS

Wind speed is an important weather factor influencing the movement of pesticides through drift. Use tools such as windsocks to monitor wind speed while you are applying pesticides. This practice will ensure that wind does not blow pesticides out of the treatment area, wasting chemicals, money, and time. Calibrated windsocks indicate wind speed from 2 to 12 miles per hour and can help agricultural producers make good decisions in the field to avoid losing chemicals to drift from wind. It is recommended to spray at wind speeds between 2-9 miles per hour. Never spray when wind speed is greater than 9 miles per hour.

(EFFICIENT) SPRAYERS

Improving the efficiency of your sprayer provides benefits to your operation AND reduces the chance of pesticides leaving your fields. Better application of the chemical makes it more effective in correcting the problem, saving time, money, and labor. There are many ways to improve the efficiency of your sprayer. For instance, choosing the correct nozzle for the type of application can avoid over or under application of chemicals. While nozzles seem like a very small part of your sprayer they are very important and worth the time and money it takes for proper selection and replacement.

Calibration is also vitally important to make sure your sprayer is applying chemicals as effectively and efficiently as possible. Please also remember to time your applications when rain is not predicted for the next 24 hours.

One last option is the opportunity to retrofit your current air blast sprayer to be an intelligent sprayer. After many years of research and field testing, the intelligent sprayer technology is available. Research confirms up to 87% less airborne drift and 40-87% reduction in spray loss beyond tree canopies.

Learn More:

https://www.clackamasproviders.org/wp-content/uploads/2014/05/Nozzle-replacement-cost-share-form.pdf

![]()

Our Source

![]()

Drinking-Water Protection

![]()

Watershed Programs

![]()

Water Quality

![]()